Basics of Ceramic Chip Capacitors

Introduction

Purpose:

- Provide an introduction to ceramic chip capacitors

Objectives:

- Describe the manufacturing process and basic structure of ceramic capacitors

- Explain the material systems and basic specifications of ceramic capacitors

- Describe some of the characteristics of ceramic chip capacitors

This presentation is a quick overview of ceramic chip capacitors. Subjects covered are: basic structure, manufacturing process, specifications, and basic characteristics.

Ceramic Capacitor Basics

- A capacitor is an electrical device that stores energy in the electric field between a pair of closely spaced plates

- Capacitors are used as energy-storage devices, and can also be used to differentiate between highfrequency and low-frequency signals. This makes them useful in electronic filters

- Capacitance Value: Measure of how much charge a capacitor can store at a certain voltage

- MLCC: Multilayer Ceramic Chip Capacitor

- Layers of ceramic and metal are alternated to make a multilayer chip

Capacitors are devices that store energy in the form of an electric field. They can also be used to filter signals of different frequencies. The capacitance value is an indicator of how much electrical charge the capacitor can hold.

Multilayer ceramic capacitors consist of alternating layers of ceramic and metal.

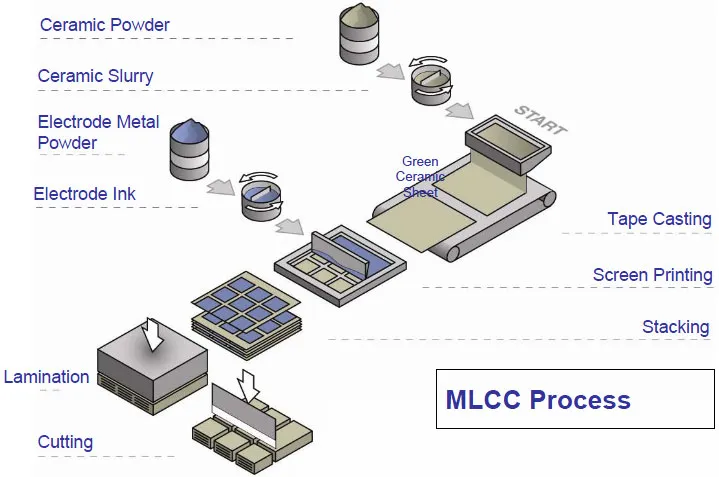

Figure 1

The process of making ceramic capacitors involves many steps.

- Mixing: Ceramic powder is mixed with binder and solvents to create the slurry, this makes it easy to process the material.

- Tape Casting: The slurry is poured onto conveyor belt inside a drying oven, resulting in the dry ceramic tape. This is then cut into square pieces called sheets. The thickness of the sheet determines the voltage rating of the capacitor.

- Screen Printing and Stacking: The electrode ink is made from a metal powder that is mixed with solvents and ceramic material to make the electrode ink. The electrodes are now printed onto the ceramic sheets using a screen printing process. This is similar to a tshirt printing process. After that the sheets are stacked to create a multilayer structure.

- Lamination: Pressure is applied to the stack to fuse all the separate layers, this created a monolithic structure. This is called a bar.

- Cutting: The bar is cut into all the separate capacitors. The parts are now in what is called a 'green' state. The smaller the size, the more parts there are in a bar.

- Firing: The parts are fired in kilns with slow moving conveyor belts. The temperature profile is very important to the characteristics of the capacitors.

- Termination: The termination provides the first layer of electrical and mechanical connection to the capacitor. Metal powder is mixed with solvents and glass frit to create the termination ink. Each terminal of the capacitor is then dipped in the ink and the parts are fired in kilns.

- Plating: Using an electroplating process, the termination is plated with a layer of nickel and then a layer of tin. The nickel is a barrier layer between the termination and the tin plating. The tin is used to prevent the nickel from oxidizing.

- Testing: The parts are tested and sorted to their correct capacitance tolerances.

- At this point the capacitor manufacturing is complete. The parts could be packaged on tape and reel after this process or shipped as bulk.

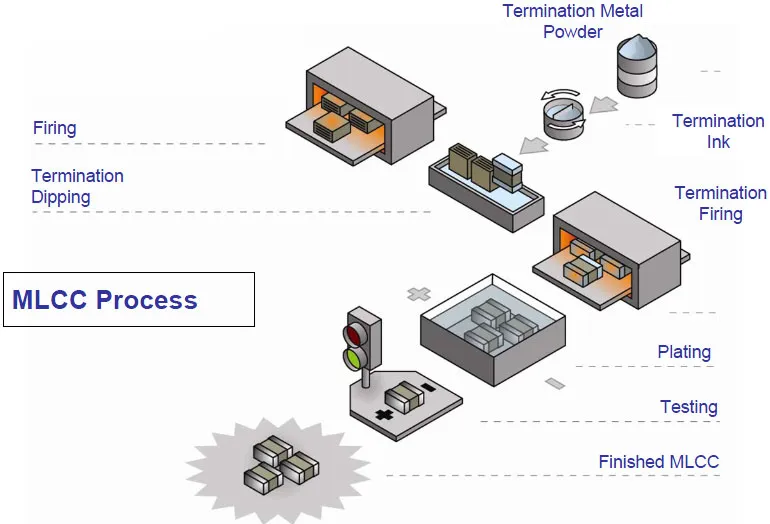

Base Metal vs. Precious Metal Systems

There are two material systems used today to make ceramic capacitors: Precious Metal Electrode and Base Metal Electrode. The precious metal system is the older technology and uses palladium silver electrodes, silver termination, then nickel and tin plating. Today this material system is mostly used on high voltage parts with a rating of 500V and higher. The base metal system is a newer technology and uses nickel electrodes, nickel or copper termination, and nickel and tin plating. This material system is typically used for parts with voltage ratings lower than 500VDC.

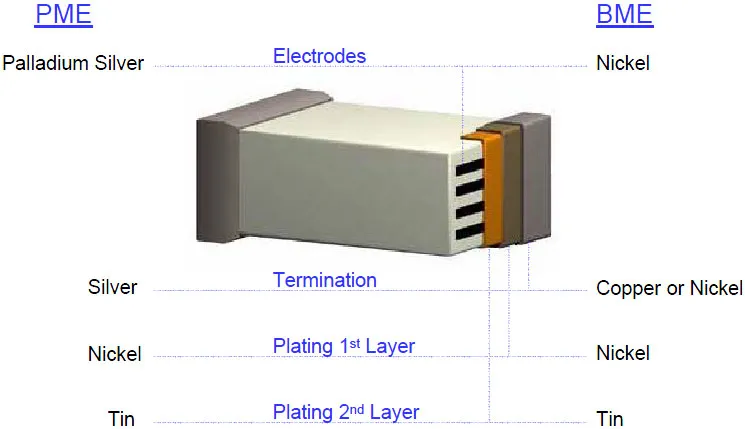

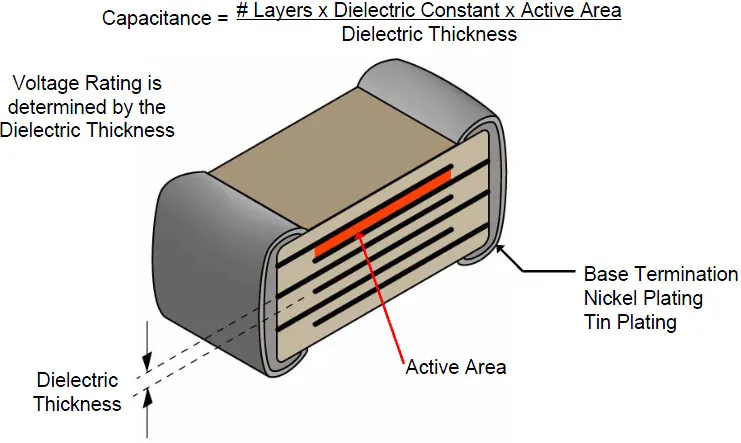

MLCC Basics

The capacitance value of a capacitor is determined by four factors. The number of layers in the part, the dielectric constant and the active area are all directly related to the capacitance value. The dielectric constant is determined by the ceramic material (NP0, X7R, X5R, or Y5V). The active area is just the overlap between two opposing electrodes.

The dielectric thickness is inversely related to the capacitance value, so the thicker the dielectric, the lower the capacitance value. This also determines the voltage rating of the part, with the thicker dielectric having a higher voltage rating that the thinner one. This is why the basic trade off in MLCCs is between voltage and capacitance.

Critical Specifications

| Material | Dielectric Constant | % Capacitance Change | DF |

|---|---|---|---|

| NP0 | 15-100 | < 0.4% (-55 to 125C) | 0.1% |

| X7R | 2000-4000 | +/-15% (-55 to 125C) | 3.5% |

| Y5V | >16000 | Up to 82% (-30 to 85C) | 9% |

- Dissipation factor: % of energy wasted as heat in the capacitor

- Dielectric Withstanding Voltage: Voltage above rating a capacitor can withstand for short periods of time

- Insulation resistance: Relates to leakage current of the part (aka DC resistance)

The critical specifications of a capacitor are the dielectric constant, dissipation factor, dielectric withstanding voltage, and insulation resistance.

Dielectric constant: this depends on the ceramic material used. The table shows differentdielectrics and some of their specifications. As you can see NP0 has the lowest dielectricconstant, followed by X7R which has a significantly higher constant, and Y5V which ishigher still. This is why the capacitance values for X7R capacitors are much higher thanNP0 capacitors, and Y5V has higher capacitance than X7R. The capacitance change vstemperature is very small for NP0 parts from -55C to 125C, and gets larger for X7R, theneven larger for Y5V. So, the more capacitance a material provides, the lower the stabilityof capacitance over temperature.

Dissipation Factor: this is the percentage of energy wasted as heat in the capacitor. Asyou can see, NP0 material is very efficient, followed by X7R, then Y5V which is the leastefficient of the three materials.

Dielectric withstanding voltage: this refers to the momentary over voltage the capacitor iscapable of withstanding with no damage.

Insulation resistance: this is the DC resistance of the capacitor, it is closely related to theleakage current.

Characteristics of Ceramic Capacitors

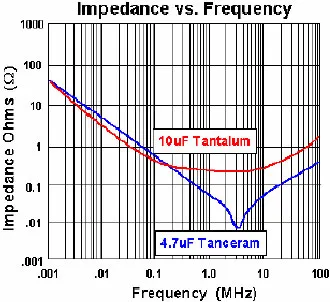

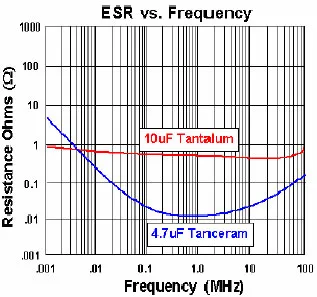

Low impedance, equivalent series resistance (ESR) and equivalent Series Inductance (ESL). As frequencies increase, ceramic has bigger advantage over electrolytics.

The final part of this presentation will cover the characteristics of ceramic capacitors.MLCCs have low impedance when compared with tantalum and other electrolyticcapacitors. This includes lower inductance and equivalent series resistance (ESR). Thisallows ceramic capacitors to be used at much higher frequencies than electrolyticcapacitors.

Characteristics of Ceramic Capacitors

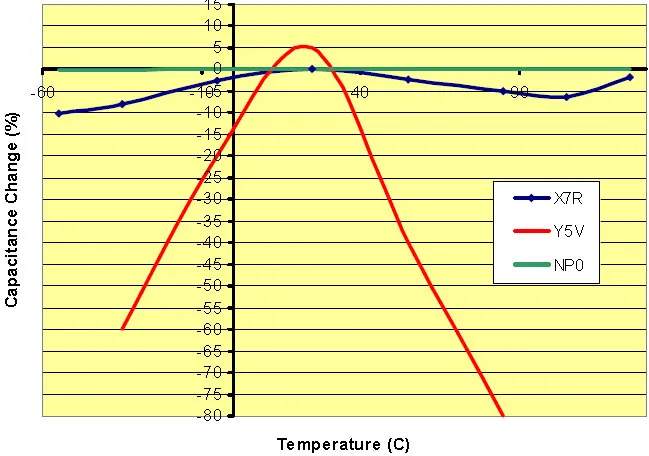

Temperature Coefficient: Describes change of capacitance vs.temperature. Ceramic materials are defined by their temperature coefficient

Temperature Coefficient of Capacitance: Describes change of capacitance vs.temperature. Ceramic materials are defined by their temperature coefficient. For example,X7R means that the capacitance can change by +/-15% across a temperature range of -55C to 125C. The graph shows the temperature coefficient of NP0, X7R, and Y5Vmaterials.

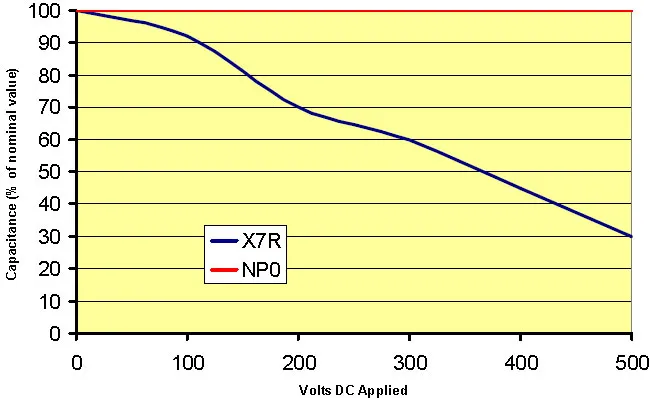

Voltage Coefficient: Describes change of capacitance vs voltageapplied. Capacitance loss can be as much as 80% at ratedvoltage. This is a property of ceramic materials and applies to allmanufacturers

Voltage Coefficient of Capacitance: describes change of capacitance vs DC voltageapplied. This is a property of ceramic materials and applies to all manufacturers. Thegraph shows typical voltage coefficient curves for 500VDC rated X7R and NP0 capactiors.Note that the capacitance of the NP0 remains stable with applied voltage, while the X7Rmaterial can have a capacitance loss of 80% at rated voltage.

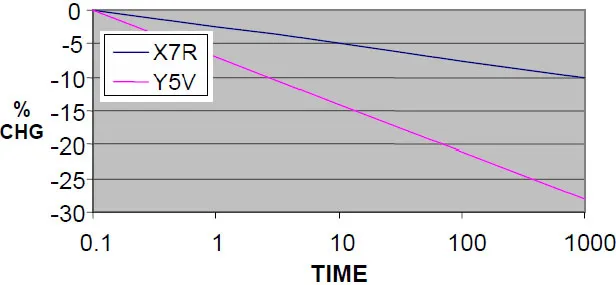

Aging: X7R, X5R, and Y5V experience a decrease in capacitance over timecaused by the relaxation or realignment of the electrical dipoles within thecapacitor.

For X7R and X5R the loss is 2.5% per decade hour and for Y5V it is 7% perdecade hour, NP0 dielectric does not exhibit this phenomenon

De-Aging: aging is reversible by heating the capacitors over the "CuriePoint" (approx 125°C), the crystalline structure of the capacitor is returned toits original state and the capacitance value observed after manufacturing.

Aging: X7R, X5R, and Y5V experience a decrease in capacitance over time caused by the relaxation or realignment of the electricaldipoles within the capacitor. For X7R and X5R the loss is 2.5% per decade hour and for Y5V it is7% per decade hour, NP0 dielectric does not exhibit any aging.

Aging is reversible by heating the capacitors over the "Curie Point" (approx 125°C), thecrystalline structure of the capacitor is returned to its original state and the capacitancevalue observed after manufacturing.

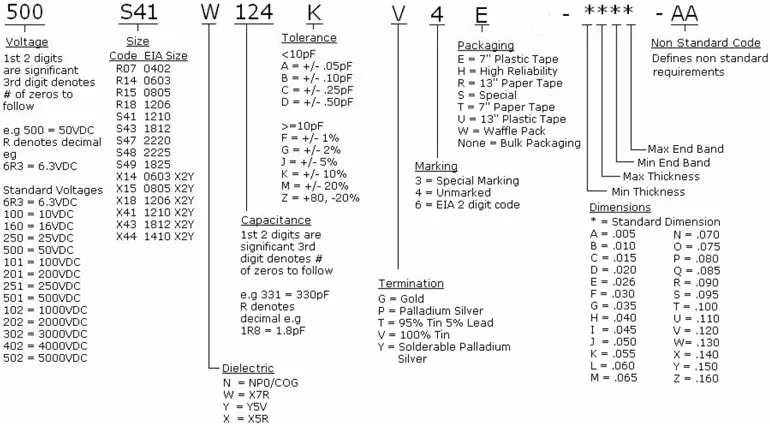

This slide is for reference and shows the Johanson Dielectrics part number breakdown.

Summary

- Manufacturing process and basic structure of ceramic capacitors

- Material systems and basic specifications of ceramic capacitors

- Precious Metal vs Base Metal

- Critical Specifications of MLCCs

- Characteristics of ceramic chip capacitors

- Low impedance, temperature coefficient, voltage coefficient, aging