Military/Aerospace & High Reliability

Overview

Johanson has over 50 years of expertise in ceramic product design and manufacturing. We excel in providing Mil Standard Qualifications, Mil-Standard screening, and COTS for Ceramic Chip Capacitors, RF Passives, and RF Inductors, catering to high-reliability applications globally.

Our facility in Camarillo, CA (USA) features a dedicated High-Reliability department with full in-house testing capabilities.

Johanson Products and Services for Military/Aerospace, and High Reliability Designers

- Mil-Standards

- Custom Products

- RF Testing Capabilities

- Quality Certifications

- Environmental Testing

- Special Testing Capabilities

Contact our engineers with your high-reliability requirements

In-House Testing Capabilities

In addition to manufacturing, the Camarillo facility has a complete High Reliability department with in-house testing capabilities.

Comprehensive Mil-Standard Testing Groups A, B & C

Electrical & Mechanical Inspections

- 100% Electrical Testing

- Cap, DF, IR, DWV, Voltage Breakdown

- 100% Visual Inspection (Mil 883 Class K or S Options)

- Full Data on Serialized Units

- Hot IR Testing

- Temperature Capacitance Coefficient (TCC)

- Temperature Voltage Coefficient (TVC)

Environmental Testing

- Burn In / Voltage Conditioning

- Life Testing

- Class H, K or S Element Evaluation

- HALT / HASS Testing

- Humidity Testing

- Moisture Resistance

- Resistance to Solder Heat

- Shear Test / Bond Pull Test

- Bend Testing

- Steam Age

- Temperature Cycling

- Thermal Shock Testing

- Shock / Vibration Testing

- Wire Bond Testing

Analytical Testing

- Destructive Physical Analysis (DPA)

- Radiographic Inspection

- SEM Inspection

- Solderability Testing

- Acoustic Microscopy (Sonoscan) Inspection

- XRF Analysis

RF & Microwave Testing Expertise

- Vector Network Analyzer Measurements

- Resonant Line Measurements for ESR at Frequency

Simulation software and designer libraries.

MLCC Termination Options

| Termination Type | Barrier to Prevent Solder Leaching | RoHS | Primary Applications |

|---|---|---|---|

| Ni/Sn | Ni | Yes | All solder applications where RoHS is required. This is Johanson’s standard termination used by the largest number of customers. Most likely to be in stock at Johanson or at Johanson authorized distributors. |

| Ni/SnPb | Ni | No | Military applications where the lead (Pb) mitigates Tin whisker growth. |

| Flexterm Ni/Sn | Ni | Yes | Flexible terminations for high physical stress applications |

| Flexterm Ni/SnPb | Ni | No | Flexible terminations for high physical stress applications |

| Ni/Au Gold Termination | Ni | Yes | Parts are epoxied in place or a mix of solder and epoxy attachment is used. Controlled Au thickness to avoid Gold embrittlement issues when soldering. Premium price. |

| Cu/Sn(Copper barrier) | Cu | Yes | This non-magnetic termination is best suited for application where very high inductance / magnetic fields are present. Use where RoHS is required. Most common non-magnetic termination. |

| Cu/SnPb(Copper barrier) | Cu | No | This non-magnetic termination is best suited for application where very high inductance / magnetic fields are present. |

| PdAg | None | Yes | No plating - solderable thick film PdAg alloy termination.Premium price. |

| PtAg | None | Yes | No plating - solderable thick film PdAg alloy termination. Premium price. |

Single Layer Termination Options

| Termination Type | Barrier to Prevent Solder Leaching | RoHS | Primary Applications |

|---|---|---|---|

| TiW/Ni/Au | Ni | Yes | Chip & Au wire where capacitor is soldered in place or a mix of solder and epoxy attachment is used. |

| TiW/Au | None | Yes | Chip & Au wire where capacitor is epoxy attached.Optimum termination for wirebonding. Cannot solder this chip as substantial leaching will occur. |

Lead-Frame Termination Options

| Termination Type | Barrier to Prevent Solder Leaching | RoHS | Primary Applications |

|---|---|---|---|

| Ni | None | Yes | Used in very high-temp applications |

| Cu/Ni/SnPb | Ni | No | Typically used in military applications |

| CuSn6 Phosphor Bronze | Ni | No | SnPb plate |

| Iron-Nickel Alloy | Ni | Yes | Sn plate |

| Pure Silver Leads | None | Yes | Used in very high power RF. Premium price. |

If you have unique needs or require additional technical information, contact your Johanson Representative or submit a technical request on our website at: https://www.johansondielectrics.com/contact/ask-a-question/

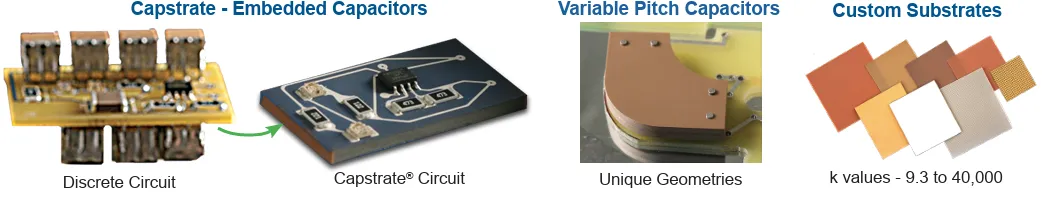

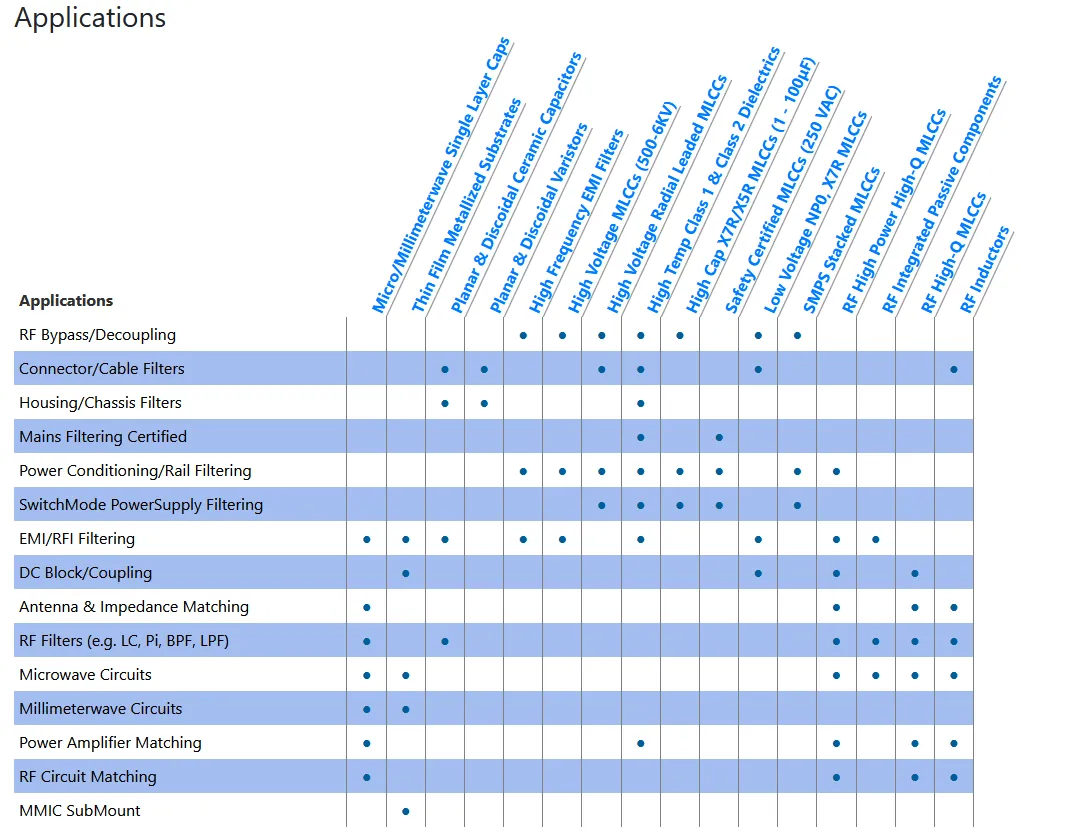

- Micro/Millimeterwave Single Layer Caps

- Thin Film Metallized Substrates

- Planar and Discoidal Ceramic Capacitors

- Planar and Discoidal Varistors

- High Frequency EMI Filters

- High Voltage MLCCs (500-6KV)

- High Voltage Radial Leaded MLCCs

- High Template Class 1 and Class 2 Dieletrics

- High Cap X7R/X5R MLCCs (1-100uF)

- Safety Certified MLCCs (250 VAC)

- Low Voltage NP0, X7R MLCCs

- SMPS Stacked MLCCs

- RF HIgh POWER High-Q MLCCs

- RF Integrated Passive Component

- RF HIgh-Q MLCCs

- RF Inductors

High Reliability North America MLCC

We specialize in high-reliability multilayer ceramic capacitors (MLCCs) engineered for aerospace, defense, medical, and other mission-critical industries.

Our capacitors, made …

Learn more about High Reliability North America MLCC