Resistor Wirewound Precision SMT

RWF Series

This specific product line is not for new designs.

Johanson’s Surface Mount Precision Wirewound Resistor (RWF Series) features ultra-tight tolerance to ± 0.01% and exhibits a temperature coefficient of as low as ± 20ppm/°C. This series offers options for low inductance windings, has good pulse handling capability and UL94-V0 flameproof protection. The small-profile design of this resistor helps satisfy the growing demand for new high density boards fabricated with automated pick and place equipment. Resistance value goes as low as 0.005 ohms, and non-inductive windings are available.

KEY FEATURES:

- Resistance from 0.005 to 50kOhms

- Precision, Flame Proof and Pulse Withstanding

- Tolerance to ± 0.01%

- High Power to 4 Watts

- Flame Resistant UL 94V-0

- Superior Surge Handling Capability

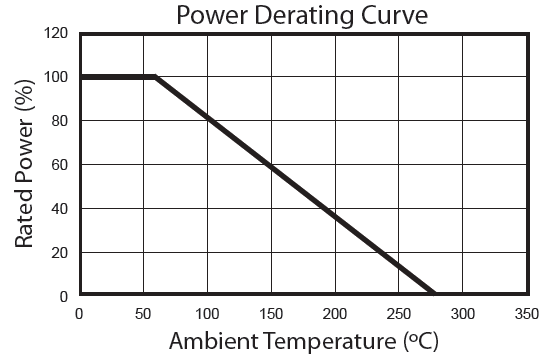

- High Temperature Rating up to 275°C

- Low Temperature Coefficient to ± 20ppm/°C

- Non-Inductive Windings available

- RoHS Compliant

APPLICATIONS:

- Motor Control

- Braking Systems

- Power Supplies

- Pressure Transducers

| PRODUCT SERIES (RWF) | RESISTANCE RANGE (Ω) 1 | POWER RATING (W) @ 70 °C | DIELECTRIC STRENGTH | TOLERANCE | TEMPERATURE COEFFICIENT | TEMPERATURE RANGE | INSULATION RESISTANCE |

|---|---|---|---|---|---|---|---|

| C1 | 0.01 to 400 | 0.5 | 1000 VAC |

± 0.01% to ± 5% |

|

- 55°C to + 275°C |

>1000 MOhms / Dry |

| C2 | 0.005 to 3k | 1 | |||||

| C3 | 0.01 to 15k | 2 | |||||

| C4 | 0.01 to 25k | 3 | |||||

| C5 | 0.01 to 50k | 4 | |||||

| D1 | 0.005 to 0.01 | 1 | 500 VAC |

± ±1% to ±5% |

± 200ppm/°C D2 0.005 to 0.07 2 Call Factory For Lower | ||

| D2 | 0.005 to 0.07 | 2 |

1 For non-inductive windings, divide max resistance by 2

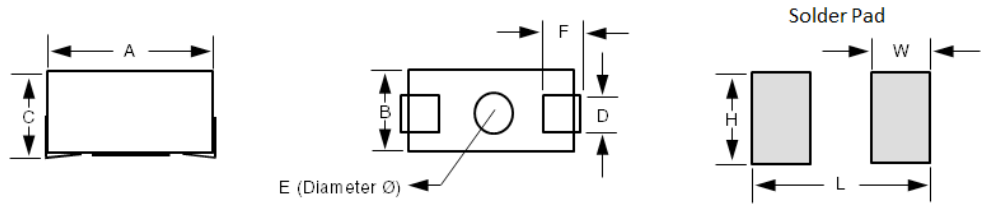

Mechanical Characteristics

Lead Thickness 0.006 [.015mm] Tolerances ±0.002” [±0.05mm]

Lead Thickness 0.006 [.015mm] Tolerances ±0.002” [±0.05mm]

| Package Code | C1 | C2 | C3 | C4 | C5 | D1 | D2 | |

|---|---|---|---|---|---|---|---|---|

Dimensions Inches [mm] |

A (Tolerances) ±0.015” [±0.4mm] |

0.190 [4.83] |

0.260 [6.60] |

0.450 [11.43] |

0.625 [15.83] |

0.820 [20.83] |

0.260 [6.60] |

0.450 [11.43] |

| B (Tolerances) ±0.015” [±0.4mm] |

0.130[ 3.30] |

0.155 [3.94] |

0.250 [6.35] |

0.270 [6.86] |

0.295 [7.49] |

0.155 [3.94] |

0.250 [6.35] |

|

| C (Tolerances) ±0.015” [±0.4mm] |

0.110 [2.79] |

0.125 [3.18] |

0.180 [4.57] |

0.250 [6.35] |

0.305 [7.75] |

0.100 [2.54] |

0.100 [2.54] |

|

| D (Tolerances) ±0.015” [±0.4mm] |

.060 [1.52] | 0.070[1.78] |

0.120 [3.05] |

0.120 [3.05] |

0.150 [3.81] |

0.070 [1.79] |

0.120 [3.05] |

|

| E (Tolerances) ±0.015” [±0.4mm]] |

0.040 [1.02] |

0.070 [1.78] |

0.100 [2.54] |

0.135 [3.43] |

0.190 [4.83] |

0.070 [1.79] |

0.100 [2.54] |

|

Stand-Off Inches [mm] |

E (Tolerances) ±0.015” [±0.4mm] |

0.100 [2.54] |

0.120 [3.05] |

0.190 [4.83] |

0.150 [3.81] |

0.245 [6.22] |

0.120 [3.05] |

0.190 [4.83] |

| Height (Tolerances) ±0.005”[±0.13mm] |

0.005 [0.13] |

0.005 [0.13] |

0.005 [0.13] |

0.005 [0.13] |

0.005 [0.13] |

0.005 [0.13] |

0.005 [0.13] |

|

Solder Pad Inches [mm] |

Width (Tolerances) ±0.015” [±0.4mm] |

0.062 [1.57] |

0.096 [2.44] |

0.150 [3.81] |

0.200 [5.08] |

0.220 [5.59] |

0.096 [2.44] |

0.150 [3.81] |

| Height (Tolerances) ±0.015” [±0.4mm] |

0.100 [2.54] |

0.150 [3.81] |

0.200 [5.08] |

0.220 [5.59] |

0.250 [6.35] |

0.150 [3.81] |

0.200 [5.08] |

|

| Length (Tolerances) ±0.015” [±0.4mm] |

0.250 [6.35] |

0.070 [1.78] |

0.540 [13.72] |

0.700 [17.78] |

0.337 [8.56] |

0.337 [8.56] |

0.540 [13.72] |

|

Environmental Performance

| Environmental Performance (MIL-STD 202) |  R Maximum R Maximum |

|---|---|

| Load Life | ±1% + 0.05 Ω |

| Moisture Resistance | |

| Dielectric | ±0.5% + 0.05 Ω |

| Storage | |

| Shock | ±0.5% + 0.05 Ω |

| Thermal Shock | |

| 5X Overload (5s) | |

| Resistance to Heat Solder (260C, 10s) |

Packaging Information

| Package Code | C1 | C2 | C3 | C4 | C5 | D1 | D2 |

|---|---|---|---|---|---|---|---|

| Reel/Tape Width [mm] | 12 | 16 | 24 | 24 | 32 | 16 | 24 |

| Small | 650 | 600 | 250 | 125 | 180 | 600 | 250 |

| Large | 3000 | 2000 | 1000 | 500 | 500 | 2000 | 1000 |

Moisture Barrier Bags (MBB) are used to package surface mount components. These bags include a dessicant and a Humidity Indicator Card to monitor humidity levels. All bags are marked with Moisture-Sensitive Identification Labels. A Moisture Sensitivity Level (MSL) rating of 2 (1-year floor life) applies to the Johanson RWF Series.

Available Options

- Special Testing Requirements

- Special Pulse Requirements

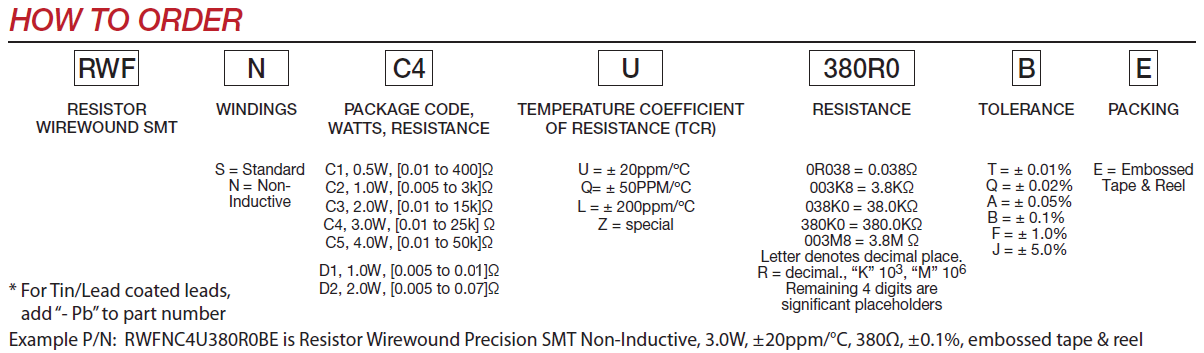

How to Order